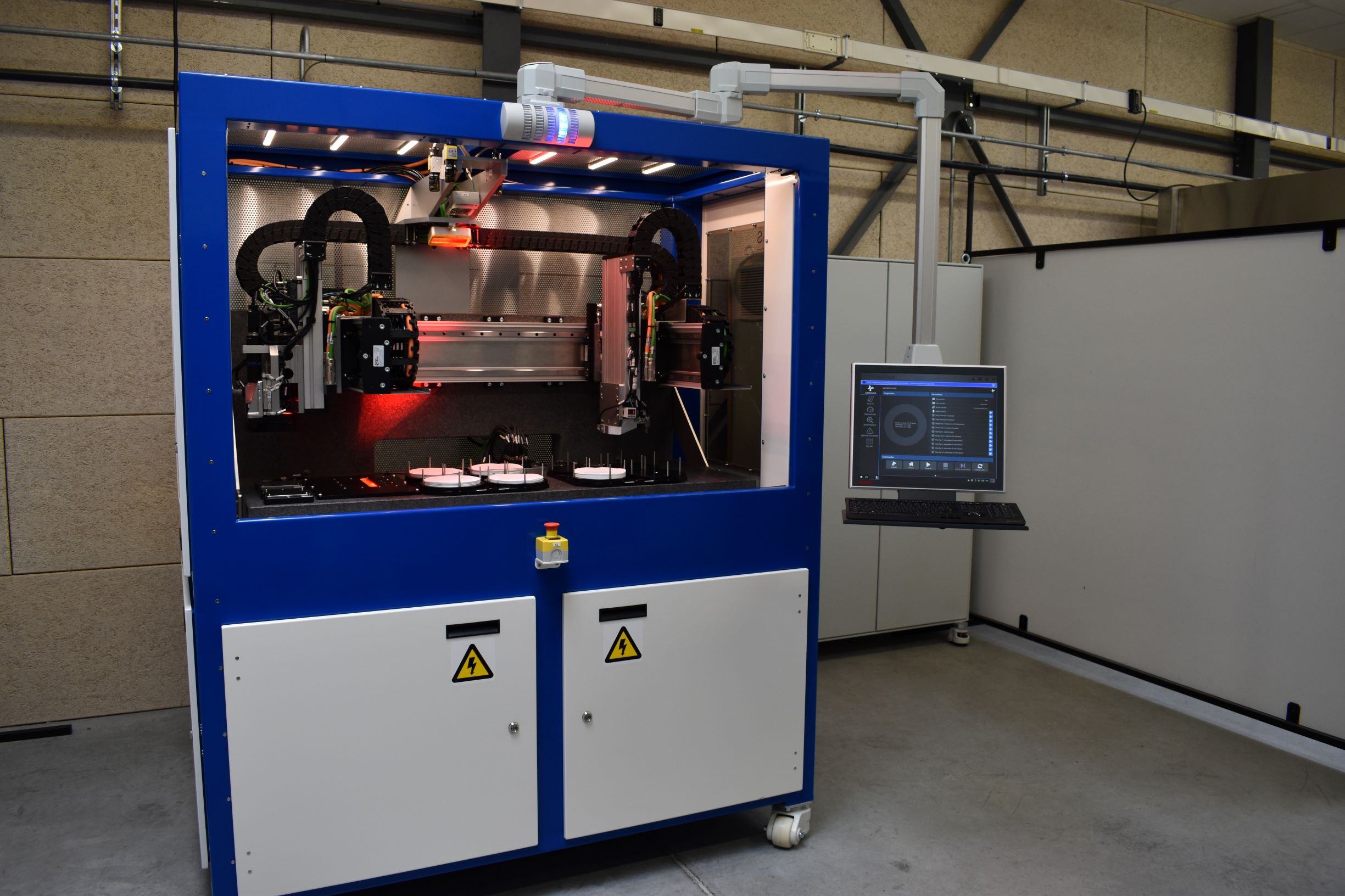

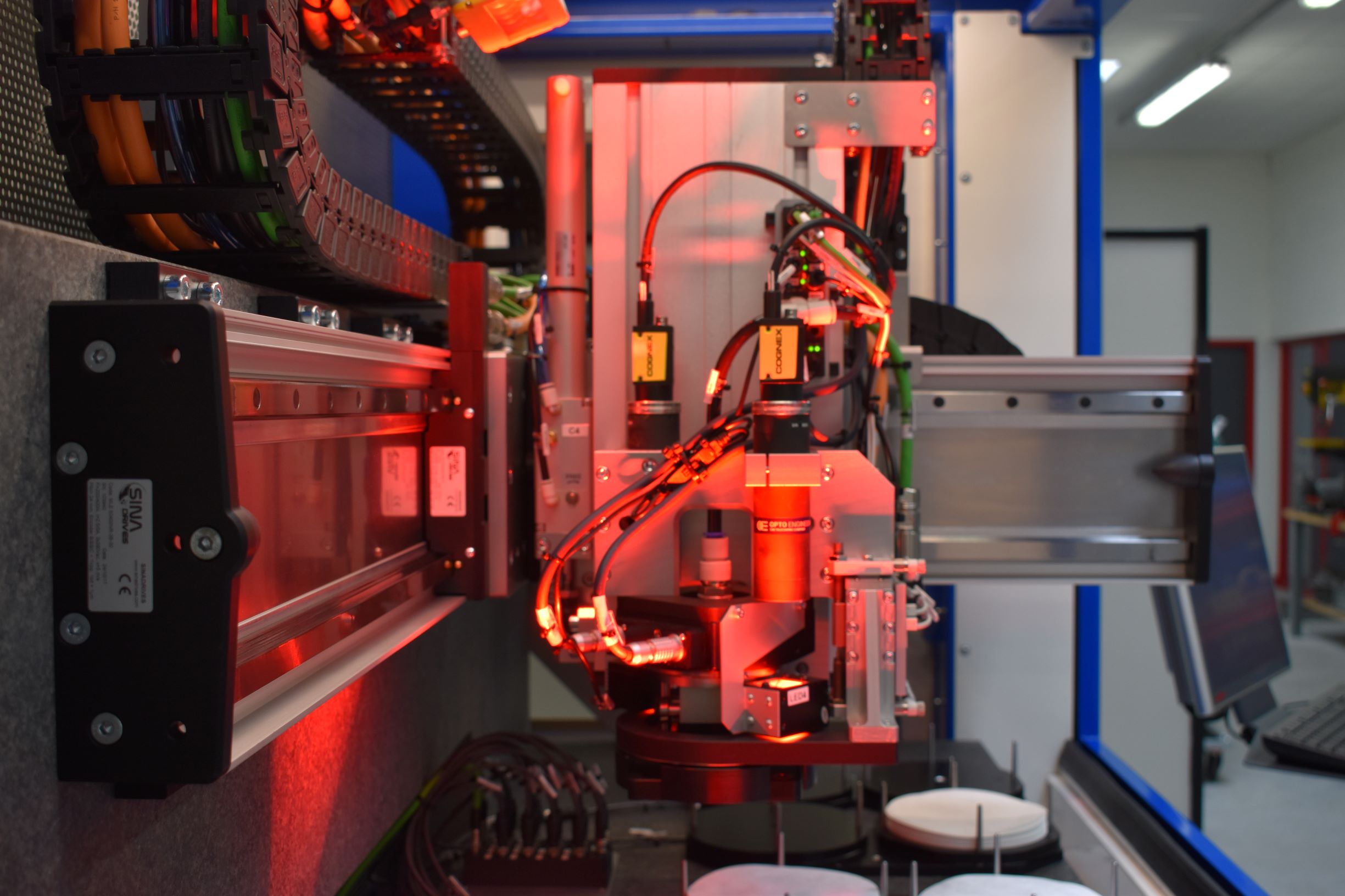

Automatic component pick & place machine

Automatic component pick & place machine for the semiconductor industry.

- Clean room, anhydrous and ESD design

- Protection by automatic door with intelligent restart (automatic process recovery)

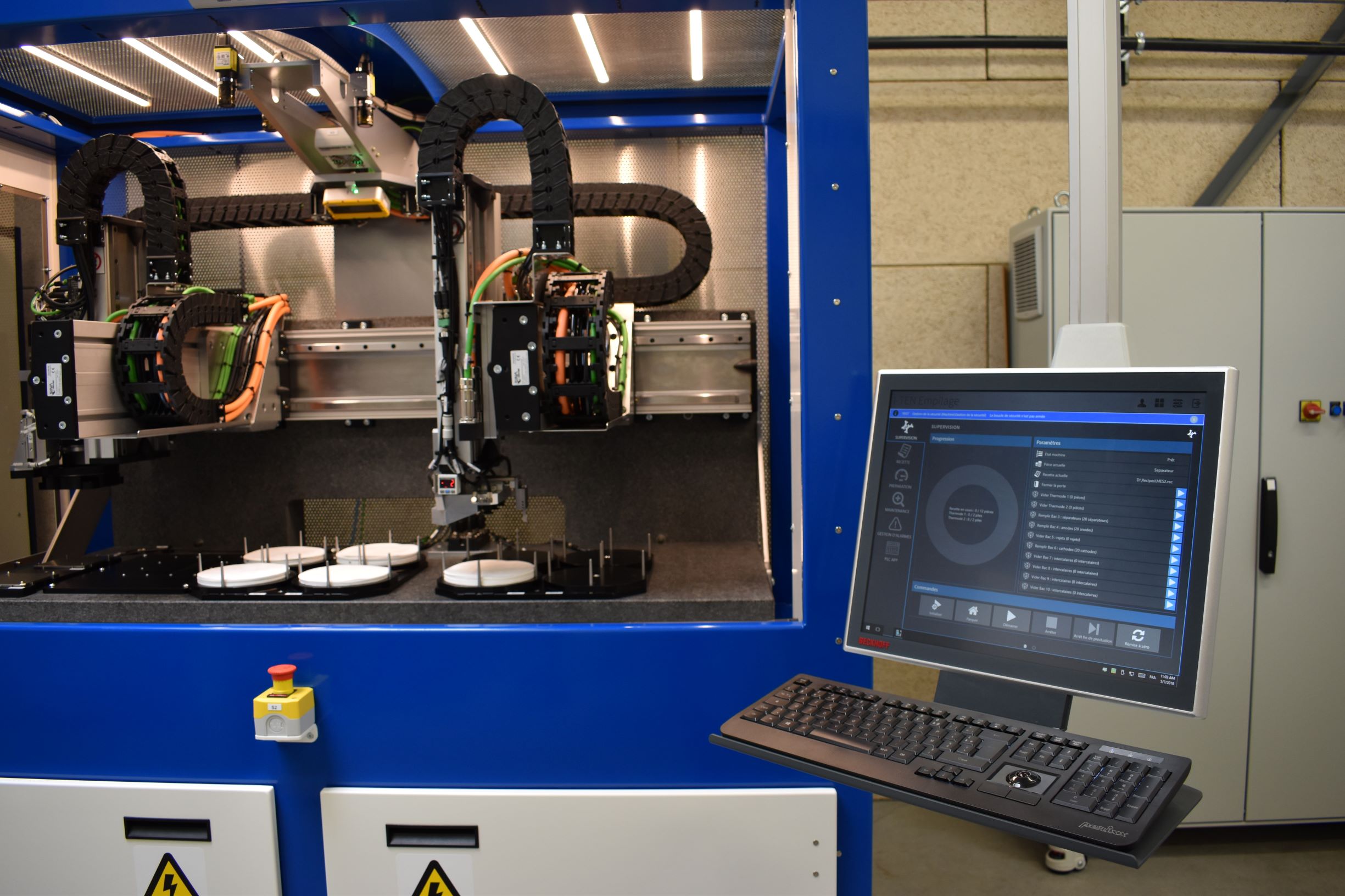

- PC base with Objectis Machine touch interface

- Vision based on Cognex VisionPro

- Inputs / outputs and axis controllers on EtherCAT fieldbus

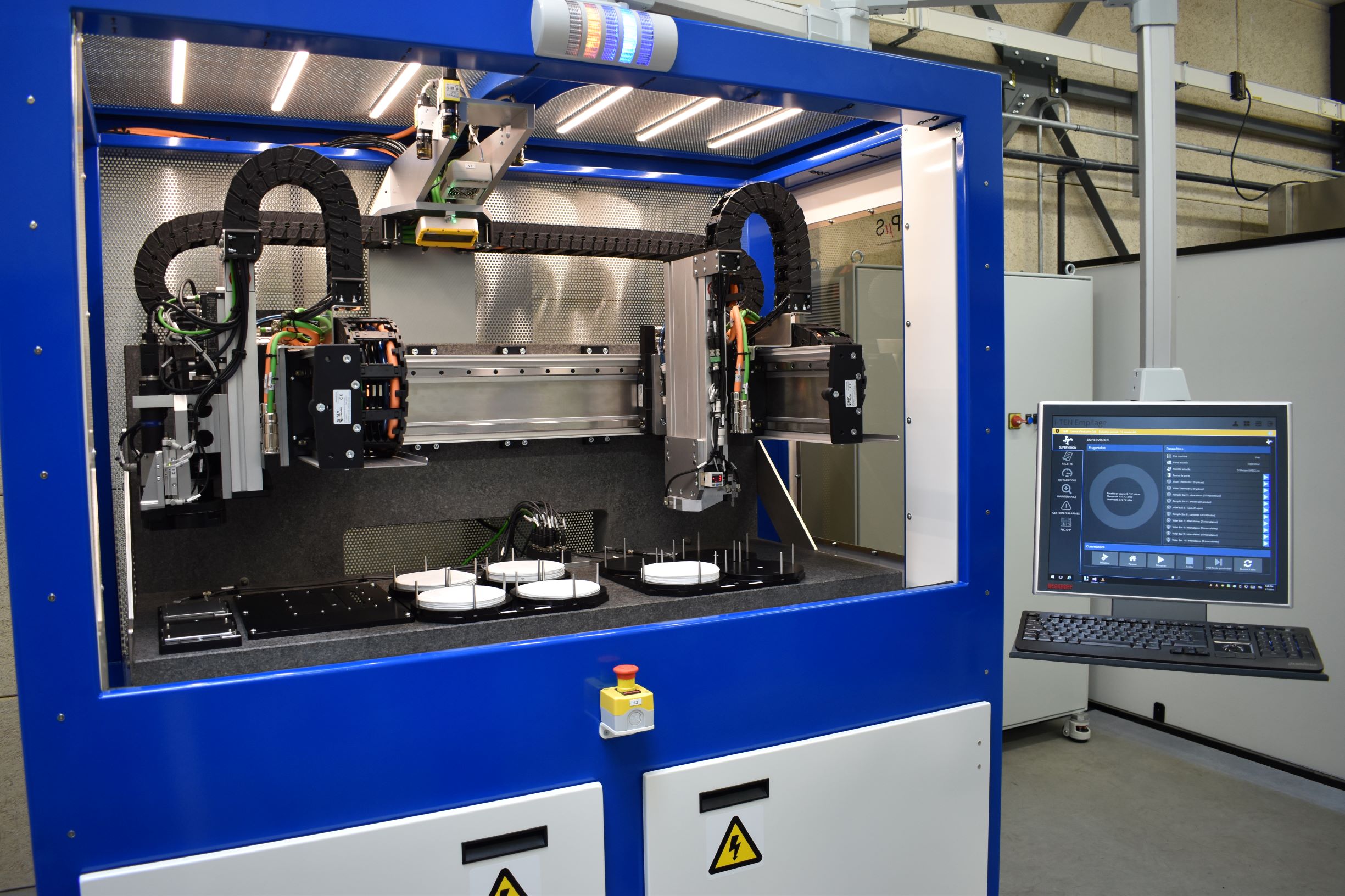

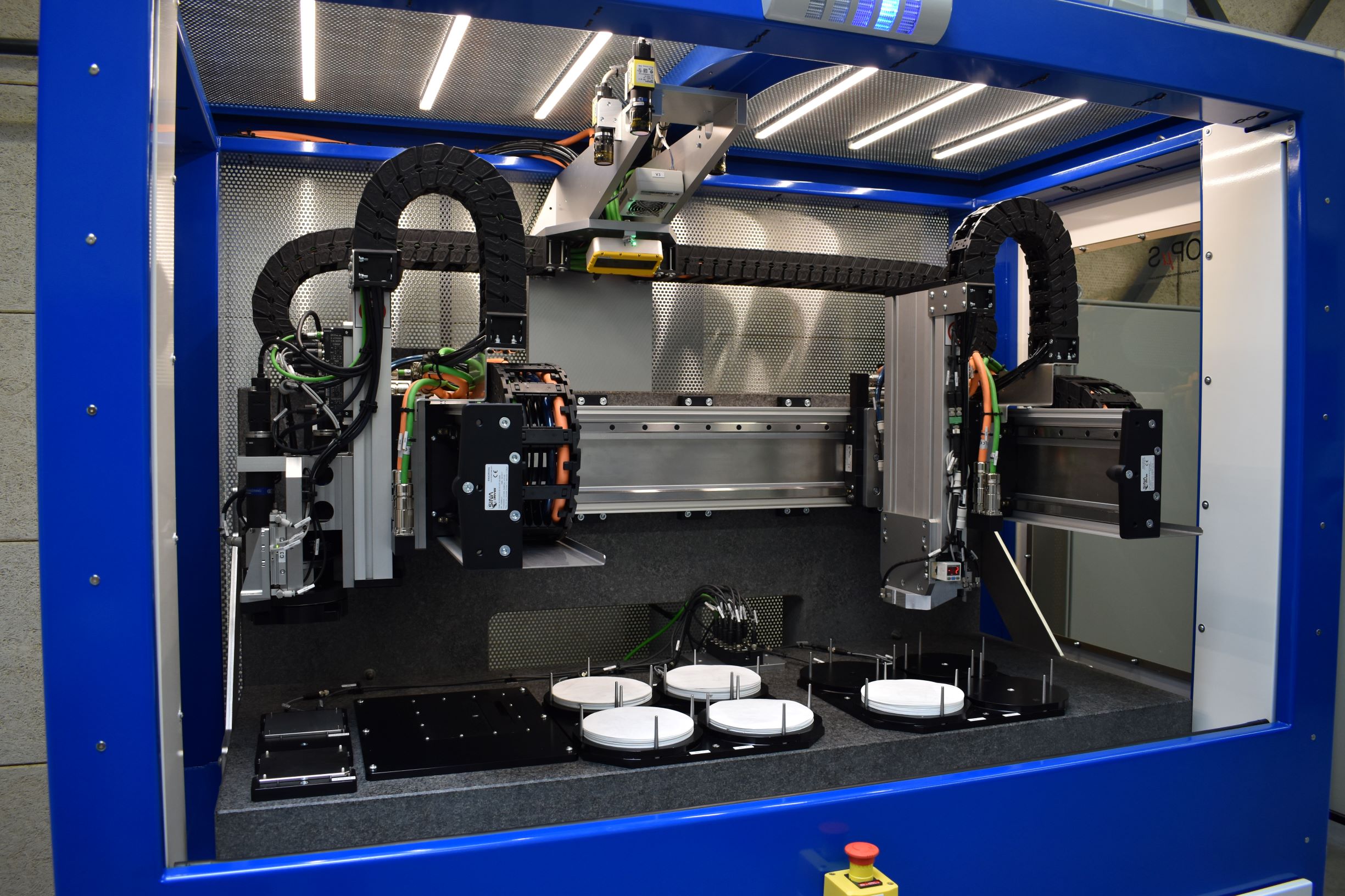

- Two linear motor robots (3 and 4 axes) working in parallel with integrated anti-collision software module

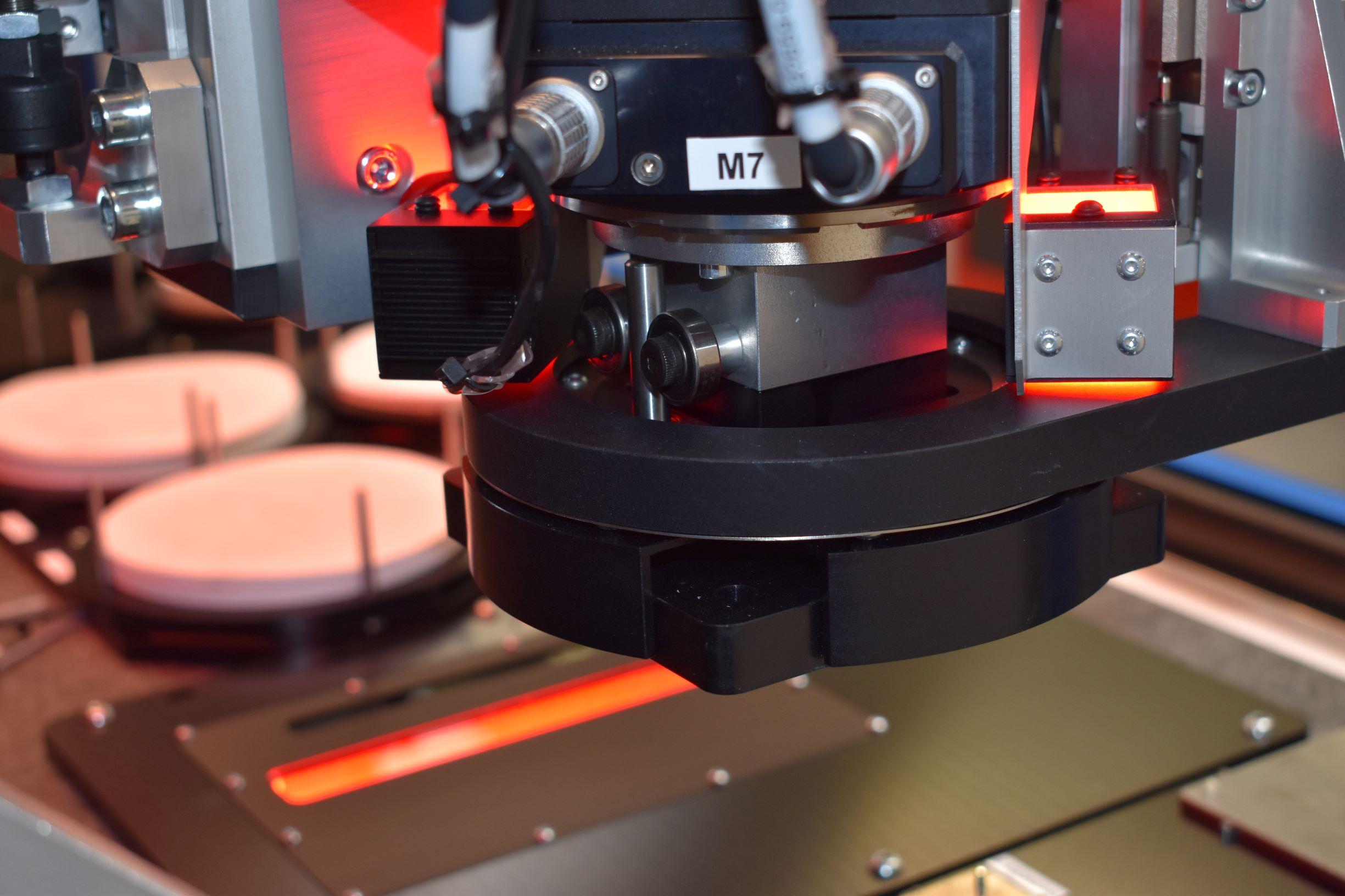

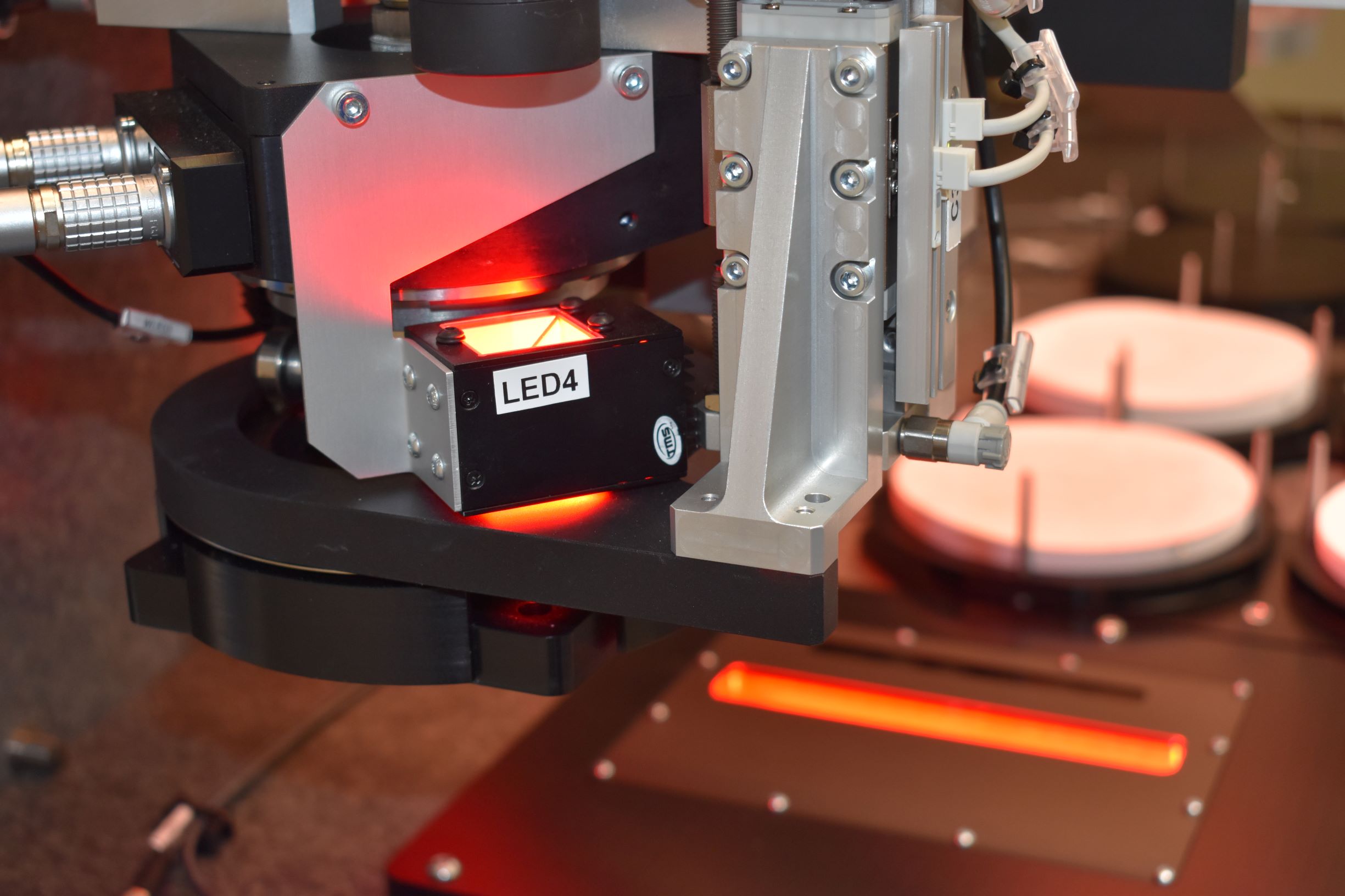

- Six cameras for real-time process control:

- Three cameras for identifying incoming products, with polarized filters to avoid metallic reflections

- Two cameras with telecentric lenses on the placement robot for component alignment

- One line-scan camera with telecentric lens and on-the-fly recording, driven by the placement axis encoder, for component control before placement

- Real-time visualization and recording of process parameters (forces, positions, images, etc.)

- Motion safety entirely controlled by software (Safety over EtherCAT) with controlled stops

- Different access levels with maintenance key

- Continuous recording of process data and generation of control reports for each assembly

- Intelligent machine monitoring routines to reduce operational downtime

- Rotary, tilting and height adjustable HMI

- Clear and measured workstation lighting